IN-HOUSE DEVELOPED SOFTWARE ‘’company

organization software’’

Old

definition doesn’t exist

New definition:

Another option is to make or develop

software internally. UPS, for example, used IS personnel, including systems,

analysts and die people who will be using the application, to develop in-house

software. Getting users involved with in-house software development can be

critical to successful systems development project. According to the vice

president of IS at UPS commenting about user input, ‘’They know they'll have to

go back to their teams and consume it.’’ Programmer productivity is also important for in-house developed

software. According to one software expert, "A programmer coding at full

throttle is keeping zillions of things in their head at once."

Some advantages inherent with

in-house developed software include meeting user and organizational

requirements and having more features and increased flexibility in terms of customization

and changes. Software programs developed within a company also have greater

potential for providing a competitive advantage because competitors cannot

easily duplicate them in the short term. Companies can also reuse software they

developed for another application. IBM for example, modified software that catches

card counters and cheats at gambling casinos so that the same could be used to

identify illegal immigrants. IBM expects to generate about S1 billion in

revenues from immigration agencies around the world by modifying its software

in this way. If software is robe developed internally, a number of tools and

techniques can be used.

(Ralph

Stair, George Reynolds, Principles of Information Systems, pg.574)

There

is no previous definition. But I found my definition is sufficient for the

purpose of understanding the meaning.

CONTINUOUS PATH ROBOTS: ‘’industrial

automation’’

Old

definition:

In continuous path robot the tool

performs its task, while the robot (its axes) is in motion, like in the case of

arc welding, where the welding pistol is driven along the programmed path. All

axes of continuous path robots move simultaneously, each with a different

speed. The speeds are controlled by storing a large number or close succession

of spatial points in the robot's memory during the teach sequence. During

teaching, and while the robot is being moved, the coordinate points in space of

each axis are continually monitored and placed into the control system's

computer memory. These are the most advanced robots and require the most

sophisticated computer controllers and and software development. Continuous path

robots are used for arc welding, spray painting, cleaning of metal particles,

complex assembly process, surveillance, etc.

(Gupta

A.K., Arora S.K., Industrial automation and robotics, 2007, p. 285)

New definition:

Continuous path motion is a

coordinated motion. The robot arm, wrist or end-effector follow a specified

path in a 3-D space. Continuous path motion is a coordinated point-to-point

motion described very closely or continuously on a time base. In this programming

method, the robot arm is led through the path describing several points at a

fixed time or in discrete time intervals. The arm may be traversed very slowly

following a point-to-point path at small intervals, or else the arm can be

moved fast following wide apart points. Thus, several hundreds of individual

points can be recorded in the controller's memory. The path of the robot may be

any curve, or an arc of a circle. In specific cases, it may be a straight line.

The recorded points along the curve may be stored in cassette tapes or floppy

disks. When the programme is on playback mode, the robot moves continuously

through the stored points as Illustrated in Fig. 1.41.

(S.R.

Deb, Robotics Technology and Flexible Automation, pg.40)

Definitions

are similar to each other I think

AUTOMATED MANUFACTURING

SYSTEMS ’’automation’’

Old

definition doesn’t exist

New deifinition:

An Automated Manufacturing Systems

(AMS) is an interconnected system of material processing stations capable of

automatically processing a wide variety of part types simultaneously under

computer control. The system is not only interconnected by a material transport

system, but also by a communication network for integrating all aspects of

manufacturing. Such a system exhibits flexibility in parts routing, part

processing, part handling, and tool changing. Additionally an automated manufacturing

system exhibits the following characteristics: high degree of automation, high

degree of integration, and high degree of flexibility. An automated

manufacturing system may include several enabling technologies such as:

computer aided design (CAD), computer aided process planning (CAPP), computer

aided manufacturing (CAM), flexible assembly and flexible manufacturing,

computer aided testing (CAT), production planning and control, process technologies,

robotics and automated material handling. It should be noted that sometimes the

terms Computer Integrated Manufacturing (CIM) and AMS are used interchangeably.

(Paul

M. Swamidass, Encyclopedia of production and manufacturing management, pg. 50-51)

There

is no previous definition. But I found my definition is sufficient for the

purpose of understanding the meaning.

POWDER COATING ’’material

application’’

Old

definition:

There are two principles application

methods for powder coatings: spraying and fluidized bed. In the spraying

method, an electrostatic charge is given to each particle in order to attract

it to an electrically grounded part surface. Several spray gun designs are

available to impart the charge to the powders. The spray guns cab ne operated

manually or by industrial robots. Compressed air is used to propel the powders

to the nozzle. The powders are dry when sprayed, and any excess particles that

do not attach to the surface can be recycled (unless multiple paint colors are

mixed in the same spray booth). Powders can be sprayed onto a part at room

temperature, followed by heating of the part to the melt the powders; or they

can be sprayed onto a part that has been heated to the above the melting point

of the powder, which usually provides a thicker coating.

(M.P.

Groover, Fundamentals of modern manufacturing, 3rd edition, p.349)

New definition:

What Is It? Dust particles stick to

the face of a television set because of a difference in electrical change

between the dust and the screen. This effect is used for practical purposes in

electrostatic powder coating. It is an efficient, widely used process for

applying decorative and protective finishes to metallic or conducting

components. The powder is a mixture of finely ground pigment and resin that is

sprayed through a negatively charged nozzle onto a surface to be coated. The

charged powder panicles adhere to the surface of the electrically grounded

component. The charge difference attracts the powder to the component at places

where the powder layer (which is insulating) is thinnest, building up a uniform

layer and minimizing powder loss. The component is subsequently heated to fuse

the layer into a smooth coating in a curing oven. The result is a uniform,

durable cooling of high quality and attractive finish.

In polymer flame coating, a thermoplastic in

powder form (80-200 µm) is fed from a hopper into a gas-air flame that melts

the powder and propels it onto the surface to be coated. The process is

versatile, can be mechanized or operated manually and can build up coatings as

thick as 1 mm. A wide range of thermoplastic powders can be used and the process

is cheap. The disadvantages: line-of-sight deposition, and surface finish that

is inferior to other processes.

A hot donut, dunked into fine sugar,

emerges with a crisp sweet skin. Fluidized- bed coating works in much the same

way. The component, heated to 200-400 C, is immersed for 1 to 10 seconds in a

tank containing coating powder, fluidized by a stream of air. The hot component

melts the particles, which adhere to it, forming a thick coating with excellent

adhesion. In electrostatic bed coating the bed is similar but the air stream is

electrically charged as it enters the bed. The ionized air charges the

particles as they move upward, forming a cloud of charged particles. The

grounded component is covered by the charged particles as it enters the

chamber. No preheating of the component is required but a subsequent hot curing

is necessary. The process is particularly suitable for coating small objects

with simple geometries.

A hot donut, dunked into fine sugar,

emerges with a crisp sweet skin. Fluidized- bed coating works in much the same

way. The component, heated to 200-400 C, is immersed for 1 to 10 seconds in a

tank containing coating powder, fluidized by a stream of air. The hot component

melts the particles, which adhere to it, forming a thick coating with excellent

adhesion. In electrostatic bed coating the bed is similar but the air stream is

electrically charged as it enters the bed. The ionized air charges the

particles as they move upward, forming a cloud of charged particles. The

grounded component is covered by the charged particles as it enters the

chamber. No preheating of the component is required but a subsequent hot curing

is necessary. The process is particularly suitable for coating small objects

with simple geometries.

(M.

F. Ashby, Kara Johnson, Materials and Design: The Art and Science of Material

Selection in Product Design, pg. 319)

My

definition is more detailed and the pictures makes it easy to understand the

how this method applied

FIXED PRODUCT LOCATION

LAYOUT ‘’process planning/assembly’’

Old

definition:

If the product is large and heavy,

and therefore difficult to move, it typically remains in a single location

during its fabrication or assembly. Workers and processing equipment are

brought to the product, rather than moving the product to the equipment. This

type of layout is referred as a fixed product location layout

(Mikell

P. Groover; Fundamentals of Modern Manufacturing Materials, Processes, and

Systems 3rd Edition; pg.18)

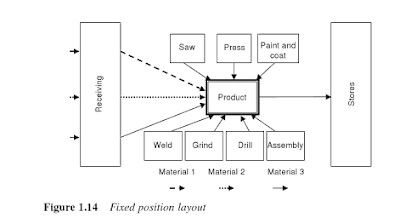

In the fixed position layout the product remains at the same location, that is, a fixed position, usually due to the size/weight of the product. The workers and all tools and equipment are then brought to the product to carry out work as illustrated in Fig. 1.14. It should be noted that component parts, subassemblies and assemblies might be manufactured elsewhere and then brought to the product location. The workers are usually highly skilled and material handling is high. It is also common for products manufactured using this layout to the one of a kind, for example, ships, aircraft, space vehicles, etc. The advantages and disadvantages of a fixed position layout are the same as those stated for project manufacture.

(Peter

Scallan, Process planning: the design/manufacture interface, pg.24)

My

definition is better than the older one, because it contains some examples and

the visual scheme to make the subject understandable.

No comments:

Post a Comment