(previous)

Trepanning, also known as the circular cutting method, is used for producing larger holes. With this method, the dimension and precision of the drill hole diameter is determined by the relative motion between the workpiece and the laser beam. This technology roughly corresponds to laser cutting. An additional increase in precision by further decomposing the drilling process in ever more individual steps becomes possible by the so-called twist drilling, developed from trepanning drilling. Various scientific investigations have proven that a drill-hole quality that has never been achieved in ceramics and steel is possible with this method.

The centerpiece of the trepanning optical system consists of three specially designed beam splitters for aimed deflection of the laser beam. During the process, all three beam splitters rotate around the fiber optical axis. This allows one to adjust a desired phase shift proportional to the radius of the helix on the material. Integrating the trepanning optical system into the polarization adjustment will further improve quality. Drag lines will be avoided, the outlet cross-sectional area will be circular, and process efficiency will increase due to higher absorption.

(Springer Handbook of Mechanical Engineering, Springer Handbook of Mechanical Engineering,p672)

(new)- better

Trepanning

is a hole-making operation where an annular groove is produced leaving a solid

cylindrical core in the centre (Fig. 6.43).In trepanning a cutter consisting of one or

more cutting edges placed along the circumference of a circle is used to

produce the annular groove. Deep trepanning, like gun drilling, is also a means

to produce accurate long holes. Deep-hole trepanning requires a pressurized

cutting fluid system and employs self-piloted cutting action.

Trepanning

is feasible if the holes have a diameter more than 50 mm. Hole depths 160

times the diameter can be

obtained in trepanning. The hole size and accuracy depend principally on the

alignment accuracy

External

Chip Removal Type In

this type, the coolant is passed to the cutting edge through the boring bar.

The chips are flushed out by the coolant through a flute located on the outer

surface. The main advantage of this design is the ease of set-up and the

minimum requirement of auxiliary equipment. The limiting factor with regard to

hole depth is that the diameter of the boring bar that is supporting the head

must be small enough to assure easy passage of chips. The boring bar is usually

25 mm smaller than the cutting diameter. In the case of smaller sizes, 75 mm or

below, this will imply a weak boring bar not capable of withstanding torque if

allowed to become too long. In spite of this limitation, this design is

popular because of its adaptability to short holes. An external chip removal

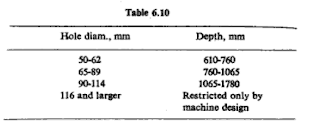

type trepanning cutter with a single cutting head is shown in Fig. 6.45a. Maximum

recommended depths for external chip removal are given in Table 6.10.

(Hmt,Hmt, H M T Bangalore, Production Technology,1980,page 179-180)

2)

BNC Connector (group : connector )

(previous)

Another type of coaxial connector that could be used in a residental system on RG58 and RG6 cable in data networking and some audio/visual applications is the Bayonet Neill Concellman (BNC) connector. The male portion (plug) of a BNC connector has a bayonet like shell with two small pins that fit into spiral slots located on the female portion (receptacle) of the connector. The plug is inserted into the receptacle and twisted into a locked position.

There are two styles of BNC connectors: a BNC-T connector and a BNC barrel connector. (All in One, 2nd Edition, Gilster&Heneveld, p.34)

There are two styles of BNC connectors: a BNC-T connector and a BNC barrel connector. (All in One, 2nd Edition, Gilster&Heneveld, p.34)

(new)- better

The most common coaxial cable

connector in use today and for some time to come is the BNC. The BNC connector

(which stands for many different names, but most often the Bayonet Neill

Concelman or British Naval Connector) is small, facilitates a quick connect/disconnect

action, and works by being screwed onto a device such as a NIC. BNC connectors

were quite popular in the early 1990s, but have since been increasingly

replaced by RJ-45 connectors used with twisted-pair cabling. BNC connectors on

coaxial cable were common on Thinnct (or 10Basc2) networks, but now arc more

often used on T-3 data network lines. The connector itself is simple to

understand;

it has two lugs on the female side of the connector that mate with the male

side. When the connectors are twisted, they are then locked into place. This

connector can be used with RG-58 to RG-179, RG-316, and many others. BNCs run

at 50 ohms. An example of a BNC termination connector is shown in Figure 8.13.

In

Chapter 7,"Fiber-Optic Media," you learned the fundamentals of

optical fiber and its practical uses, and were introduced to fiber-optic

connectors. The next section focuses on what you need to know about the

termination of fiber-optic cabling, and contains additional details about the

connectors used to terminate optical fiber. We cover the most commonly used

connector types (SC and ST), when to use each one, and why.

(Robert Shimonski,Richard T. Steiner,Sean M. Sheedy, Network Cabling Illuminated,2006,page 223-224)

3)Thermal Deburring (group : manufacturıng process )

Thermal energy deburring consists of placing the part in a chamber which is then injected with a mixture of a natural gas an oxygen. When this mixture ignited, a heat wave is produced with a temperature of 33000C (6000F). The burrs heat up instantly and are melted away, while temperature of the part reaches only about 1500C (300F).

This process is effective in very various applications on non-combustible parts. There drawbacks, however: larger burrs or flashes tend to form beads after melting; the process can distort thin and slender parts; and it does not polish or buff the work piece surfaces as do several other deburring processes.

Thermal energy deburring consists of placing the part in a chamber which is then injected with a mixture of a natural gas an oxygen. When this mixture ignited, a heat wave is produced with a temperature of 33000C (6000F). The burrs heat up instantly and are melted away, while temperature of the part reaches only about 1500C (300F).

This process is effective in very various applications on non-combustible parts. There drawbacks, however: larger burrs or flashes tend to form beads after melting; the process can distort thin and slender parts; and it does not polish or buff the work piece surfaces as do several other deburring processes.

(Kalpakjian, Smith; Manufacturing Engineering and Technology 4th Edition; pg. 736,737)

(new)- better

INTRODUCTION

Over the years, industry has made great strides using modern machining methods which have increased productivity and improved the quality ol manufactured parts. However, most of the attention has focused on primary machining methods, while finishing and deburring parts has been largely ignored. Today, 10% (and sometimes much more) of total manufacturing costs are spent on manual deburring.

All designers should consider deburring because it is so often a problem. Some machine shops insist that their parts are burr free. Burrs may be tolerable, but they are generally not desirable. Very often, groups of operators are put to work hand deburring parts for aesthetic reasons or because the parts will not function properly with burrs present

When the engineer determines that deburring must be done, there really are alternatives. First of all, he can consider various machining methods which might preclude the necessity of deburring. Then he can choose between four machine methods of deburring. which shall all be reviewed in this book.

Around 1975, a commercial process was developed to offer industry an alternative to costly hand deburring—the process became known as the Thermal Energy Method of deburring (TEM). It is the fastest method in existence. Not counting loading and unloading time, the actual deburring time is less than 30 milliseconds.

THE PROCESS

The manufactured parts, with burrs, are placed in a thick-walled chamber which is sealed and pressurized with a mixture of oxygen and natural gas. (The ratio of oxygen to gas is 2*6:1.)

The chamber is closed and sealed with a toggle mechanism exerting a force of 250 tons. The gas mixture fills each nook and cranny of all parts in the chamber (even blind and intersecting holes): and the combustible mixture is ignited by a 30,000 volt spark which creates a 6000° F heat wave. (See Fig. 19.1.) in a few milliseconds, the fuel is burned out But since most burrs exhibit a high surface area-to-mass relationship, the burr cannot transfer heat to the main part fast enough to prevent its bursting into flames. Thus, the burr becomes a source of fuel and will continue to vaporize until the heat is transferred to the part itself. As the heat moves into the part the flame temperature drops until it extinguishes itself. By this time, all burrs, chips, and contaminants have been vaporized.

In the process of vaporizing, the burrs become oxides of the metal being processed: aluminum oxide from aluminum parts and iron oxide from steel parts. The oxide settles on the partsas a loose powdery residue. Although the surface will appear discolored, it has not been oxidized and the discoloration will wash off with a suitable cleaner. A cleaning step can be avoided if the deburred parts are to be heat treated, bright dipped, black oxided. anodized. or otherwise treated or plated.

If postcleaning should be necessary to make the parts more presentable, cleaning equipment is available from the same company which manufactures the TEM machine. As a matter of fact, whenever you discuss deburring with a machine builder, you should also discuss cleaning if it is going to be required. The complete finished part is your goal, and if cleaning is significant, it should be part of the manufacturing strategy. This is especially true when the cost of cleaning equipment equals the cost of the deburring machine.

The list of industries which are taking advantage of TEM is growing annually. The most recent technical advance was the ability to process plastics as well as metals. TEM is really another manufacturing tool to be used when the situation warrants. The design engineer should consider the deburring problem before completing his design. Recently, the author watched a crew of six operators hand deburring rocket tails. The job took an average of thirty minutes per part and it left unwanted scratches on the surface. Fifty percent of the cost of that part was deburring.

(James A. Brown, Modern manufacturing processes,1991, page 149-151)

4)Adhesive (group : binding material)

(previous)

(previous)

Adhesives are polymers used to join other polymers, metals, ceramics, composites, or combination of these material. The adhesives are used for a variety of applications. The most critical of these are the " strıctural adhesives", which find use in the automative, aerospace, appliance, electronics, construction, and sporting equipment areas.

Chemically Reactive Adhesives These adhesives include polyurethane, epoxy, silicone, phenolics, anaerobics, and polymidies. One-component systems consist of a single plymer resin cured by exposure to moisture, heat, or- in the case of anerobics- the absence of oxygen. Two-component systems (such as epoxies) cure when two resins are combined).

Evaporation or Diffusion Adhesives The adhesive is dissolved şn either an organic solvent or water and is applied to the surfaces to be joined. When the carrier evaporates, the remaining polymer provides the bond. Water-base adhesives are preferred from the standpoint of environmental and safety considerations. The polymer may be completely dissolved in water ır may consist of a latex, or a stable dispersion of polymer in water. A number of elastomersi vinyls an acrlics are used.

Chemically Reactive Adhesives These adhesives include polyurethane, epoxy, silicone, phenolics, anaerobics, and polymidies. One-component systems consist of a single plymer resin cured by exposure to moisture, heat, or- in the case of anerobics- the absence of oxygen. Two-component systems (such as epoxies) cure when two resins are combined).

Evaporation or Diffusion Adhesives The adhesive is dissolved şn either an organic solvent or water and is applied to the surfaces to be joined. When the carrier evaporates, the remaining polymer provides the bond. Water-base adhesives are preferred from the standpoint of environmental and safety considerations. The polymer may be completely dissolved in water ır may consist of a latex, or a stable dispersion of polymer in water. A number of elastomersi vinyls an acrlics are used.

Hot-Met Adhesives These thermoplastic polymers and thermoplastic elastomers melt when heated. On cooling, the polymer solidifies and joins the materials. Typical melting temperatures of commercial hot-melts are about 80°C to 110°C, which limits the elevated-temperature use of these adhesives. High-performance hot-melts, such as polyamides and polyesters, can be used up to 200°C

Pressure-Sensitive Adhesives These adhesives are primarily elastomers or elastomer copolymers produced as films or coatings. PRessure is required to cause the polymer to stick to the substrate. They are used to produce electrical and packaging tapes, labels, floor tiles and wall coverings, and wood-grained textured films.

Conductive Adhesives Apolymer adhesive may contain a filler material such as silver, copper, or aluminum flakes or powders to provide electrical and thermal conductivity. In some cased, thermal conductivity is desired but electrical conductivity is not wanted; alumina, beryllia, boron nitride, and silica may be used as fillers to provide this combination of properties.

(Askeland,D.R,The Science and Engineering of Materials,3rd Edition, pg.514-515)

(new) - better

Adhesrves are defined as nonmetallic substances

capable of joining materials by surface bonding (adhesion), the bond itself

possessing adequate internal strength (cohesion). Adhesive is a generic term

and covers other common terms, such as glue, paste, gums, adhesive cement, and

bonding agent.

Composition. An adhesive is composed of basic

raw malcriáis, which are called binders 11] and which

determine ils adhesiveness (adhesion) and its internal strength (cohesion), and

of frequently necessary auxiliaries, which establish particular end-use and

processing characteristics. The adhesiveness of an adhesive, its internal

strength after setting, and its processing characteristics are the fundamental

properties that determine its suitability for use in forming adhesive joints.

Adhesive joints are the joints formed between substrates and adherents using

adhesives.

The

binders used for adhesives are primarily high polymers having optimal strength

properties. High interna! strength (cohesion) is essential if the adhesive in

an adhesive joint is to be able to transmit forces from one adherent to the

other. Most adhesives contain high molecular mass organic substances as their

basic raw materials or reactive organic compounds that are preliminar)' stages of polymers and that read during the

bonding process to form polymers. Inorganic polymers, such as the various types

of waterglass, are used only to a very limited extent.

Virtually

any standard polycondensatc, homopolymer, and copolymer and also polyadducts

may be used, provided they can be applied as solutions, dispersions, emulsions,

or melts. In addition to these raw materials, auxiliaries such as resins,

plasticizers, fillers, thickeners, solvents, antiagers, preservatives,

hardeners, or selling retarders, arc required, depending on the end use. Their

function is inter alia to adjust tack, to improve adhesion, lo make flexible,

to regulate viscosity, to stabilize, and to influence setting or hardening.

(Gerhard Gierenz, Adhesives and Adhesive Tapes, 2001, page 1-2)

5)BMEP (group : parameter)

(previous)

The most common mean effective pressure is the Brake Mean Effective Pressure or bmep, The adjective brake refers to measurement of the flywheel. Originally power output was measured by applying an ordinary brake to the flywheel, the brake being attached to a long arm, and the moment produced was measured. The power produced by the engine is proportional to the product of the moment produced and the angular rotational speed. This break was a primative dynamometer, and was developed by F. M. Riche, Baron de Prony. And it was known as a Prony brake.

(John Leask Lumley, Engines an Introduction,first edition, page 16)

(new)- better

The four modes (strokes) of the internal

eombustion engine are more clearly defined in a pressure-volume, or P-V

diagram. Figure 1.26 illustrates the four strokes in detail for a cold motoring

engine (dotted traces) and a firing engine (solid traces). The P V diagram is

taken at the standard mapping point of 1500 rpm, 2.62 bar BMEP and A,'F ratio

of 14.6:1 (i.e. world-wide mapping point). These terms will he defined shortly.

Mean effective pressure. MF.P, is the value

of constant pressure that would need lo be applied to the piston during the

expansion stroke that would result in the same work output of the engine cycle.

Equation (1.36) illustrates the definition of MEP:

Torque and volume arc in Nm

and liters, respectively.

To

understand brake mean effective pressure, BMEP, as used in Figure 1.23 it is

necessary to first understand indicated mean effective pressure, IMF,P,

mechanical efficiency, >jM,

indicated specific fuel

consumption, ISFC, indicated specific air consumption, ISAC and volumetric

efficiency, r;,.. 'Indicated' refers to the net process such as work or power

performed by the working mixture in the cylinder acting on the piston over the

compression and expansion strokes. 'Brake' means the torque or power at the

engine crankshaft measured at the flywheel by a dynamometer [13|. 'Friction'

refers to the work required to overcome engine mechanical friction and pumping

losses (work is necessary to induct the air fuel mixture into the cylinder and

to expel the excess spent charge). These terms are defined us follows:

Equation (1.38) defines the mechanical

efficiency of the engine in terms of its brake and friction MEPs. Fuel

consumption, BSFC, is then defined as the indicated specific fuel consumption,

ISFC, defined later, diverted by engine mechanical efficiency. Engine

volumetric efficiency is a measure of how close the engine is to a positive

displacement air pump. Volumetric efficiency is defined as the ratio of actual air

flow through the engine to its ideal air flow, where 'ideal' is defined as (he

displacement volume filled with a fresh charge at standard temperature and

pressure. Volumetric efficiency is dependent on valve number and size (4 V is

more efficient than 2 V. for

example), the valve lift and profile, manifold dynamics, tuning and losses, and

the heat transfer during the induction process (minimal):

Making the appropriate unit conversions leads

to the definition of* volumetric efficiency as stated in (1.41):

where the air charge is corrected for

temperature and pressure deviations from STP. Engine speed is given in rpm and

cylinder displacement in liters.

(John M. Miller, Propulsion Systems for Hybrid Vehicles,page 38-40)

No comments:

Post a Comment