SURROGATE DATA

TEST

Group: dynamic

analysis

Old

definition:

The

method of surragate data has become a central tool for validating the results

of nonlinear dynamic analysis. The surrogate data method tests for a

statistical difference between a test statistics (e.g. complexity/fractal

metrics) computed for the original time series and for an ensemble of test

statistics computed on linearised version of the data, the so-called

"surrogate data". The major aspects of the surrogate data that need

to be considered are:

1.the

definition of the null hypothesis about the nonlinear dynamics underlying a

given time series

2.the

realization of the null hypothesis, i. e., the generation method for the

surrogate data

3.the

test statistic.

(Ali-Nait, A., Advanced Biosignal Processing, p.

322)

New definition:

Surrogate

data methods are now almost invariably applied to potentially nonlinear time series

data with the aim of discounting more hum-drum linear noise processes as the

source of the observed phenomenon [23]. For the uninitiated, the entire

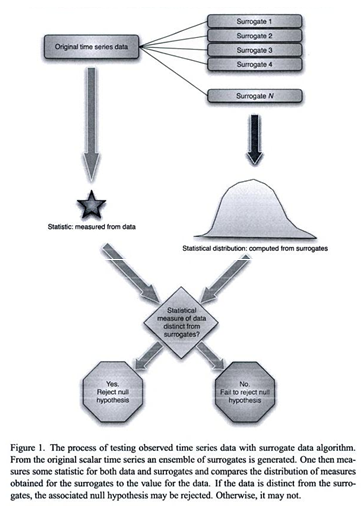

procedure can be briefly de-scribed as follows. One starts with an observed

time series which is to be tested against the null hypothesis of the surrogate

data test. The standard surrogate data repertoire provides algorithms to test

against the hypotheses of (i) independent and identically distributed noise; (ii)

linearly filtered noise; or (iii) a monotonic nonlinear transformation of

linearly filtered noise. Algorithms for each of these three hypotheses generate

an ensemble of fake (artificial) time series data: the surrogate data. These

surrogate data sets are guaranteed to have both the properties associated with

the underlying null hypothesis and also are otherwise similar to the original

observed data. In other words, these surrogate data are what independent

repeated observations of the process that generated the original data would

yield if that process were consistent with the null hypothesis. Now, one simply

evokes whatever statistic is of interest (correlation dimension is a fairly

orthodox choice) and compares the value of this statistic computed from the

data to the distribution of values elicited from the surrogates. If the

statistic value of the data deviates from that of the surrogates, then the null

hypothesis may be rejected. Otherwise, it may not. Figure I summarises this

process.

Surrogate

data methods are often applied in conjunction with either linear or nonlinear

modelling regimes. In some sense, surrogate data methods are equivalent to

applying specific classes of (usually) parameter free models. In this context

surrogate data methods can even be applied to test the residuals of specific

models [I7]. However, the purposes of hypotheses testing and modelling are

different. A model' will give a wealth of information about features that may

or may not be in the data: the features one deduces from the model are

attributable to that particular description of the data. On the other hand,

surrogate methods provide a rigourous test of whether or not the data belongs

to a particular class of systems. One can then be assured (or at least

persuaded) that the data are amenable to that particular class of models, or

not.

However,

one may still think that it is possible to investigate features of data by

modelling, for example, discrimination between linearity and nonlinearity. One

simple example is as follows. To build time series models, a particularly

convenient class is the pseudo-linear models, which are formed by linear

combination of any type of functions such as linear and nonlinear functions

They have been applied widely for building models of actual time series. When

models we build contain nonlinear functions, one may think that as the data

include nonlincarity, nonlinear functions are selected. On the other hand, when

models contain only linear functions, one may think that as the data are

linear, nonlinear functions are not selected.

v

Older definition is more useful

for general understanding about the word. But mine is more detailed for

mathematical understanding.

OPTICAL-FIBER PYROMETERS

Group:

measurement and process control

Old

definition:

Optical-fıber

pyrometers are one of the most successful optical-Eber sensors in the field of

process control in manufacturing. Typical applications are:

-Casting

and rolling lines in steeland other metal plans

-Electric

welding and annealing

-Furnaces

in chemical and metal plants

-Fusion,

epitaxial growth, and sputtering processs in the semiconductor industry

-Food

processing, paper manufacturing, and plastic processing

(Soloman S., Sensors and Control Systems in

Manufacturing, p.336)

New definition:

A

section of these devices merely use an optical fibre to direct the emitted

radiation to the detector. Strictly speaking, this section of fibre-optic

devices is not a class by itself. The first such sensors used a sapphire rod of

3 mm diameter to pick up the energy from the target and transmit it to a

detector. Contemporary fibre-optic pyrometers use a flexible bundle of glass

fibres with or without a lens. The spectral response of these fibres extends to

about 2 µm,

though sonic materials such as fluorides have a wider band-pass. Some are

useful at target temperatures FIS low as 100 °C. Beyond collection of radiant

energy, fibre-optic glasses can be doped to serve directly as radiation emitters

at hot spots so that the fiber optics serve as both the sensor and the media. A

sapphire probe is commercially available that has the easing end coated by a

refractory metal forming a blackbody cavity. The thin, sapphire rod thermally

insulates and connects to an optical fibre as is shown in Fig. 10.48. A ratio

method may be utilised to determine the temperature.

Fibre-optic

thermometers are especially useful where it is difficult, dangerous or

impossible to obtain or maintain a clear sighting path to the target, as in

pressure or vacuum chambers. Fibre-optic thermometers have also been used to

measure temperatures of turbine blades in gas turbines, and the temperature of

small objects in induction heating coils. Next we pass on to an important

aspect of temperature measurement which is considered necessary for all kinds

of thermal probes. Of course, remote measurements by pyrometers, having no

probes, do not come under its purview.

(Ghosh,

Introduction to Measurements and Instrumentation, pg.348)

v My definition is more sufficient for

explaining how the pyrometer works

MURA

Group: production

| manufacturing wastes

There

is no old definition

New definition:

Mura

refers to unevenness or fluctuation in work, usually caused by fluctuating

production plans. A simple example might be a production line that is producing

difficult models for half the shift and simple models for the second half, so

that workers strain for half the day and coast the other half. The lean system

seeks to reduce mura through heijunka, or production levelling, by mixing

models, for example.

Mura is

traditional general Japanese term for unevenness, inconsistency in physical

matter or human spiritual condition. It is also a key concept in the Toyota

Production System and is one of the three types of waste (Muda, Mura. Muri; it

identifies. Waste reduction is an effective way to increase profitability. Toyota

merely picked up these three words with prefix mu-, which every Japanese know,

as product improvement program or campaign.

Mura is

avoided through Just In Time systems which are based on little or no inventory,

by supplying the production process with the right part, at the right time, in

the right amount, and first-in, first out component flow. Just in Time systems

create a "pull system" in which each sub-process withdraws its needs

from the preceding sub-processes, and ultimately from an outside supplier. When

a preceding process does not receive a request or withdrawal it does not make

more parts. This type of system is designed to maximize productivity by

minimizing storage overhead. For example:

1. The assembly line “makes a

request to,” or “pulls from” the Paint Shop, which pulls from Body Weld.

2. The Body Weld shop pulls from

Stamping.

3. At the same time, requests are

going out to supplliers for specific perts, for the vehicles that have been

ordered by customers.

4. Small buffers accommodate minor

fluctuations, yet allow continuous flow.

If parts or material defects

are found in one process, Just-in-Time approach requires that the problem be quickly

identified and corrected.

(Pascal Dennis, Lean Production Simplified: A

Plain Language Guide to the World's Most Powerful production System, pg. 25)

(David A. Hounshell, From the American System to

Mass Production, pg.486)

v

My definition is satisfactory

for understanding this approach.

PRESENT WORTH

METHOD

Group: evaluation

of engineering alternatives

Old

definition:

The

present worth method uses the equivalent present value of all current and

future cash flows to evaluate the investment proporsal.The future cash are

converted into their present worth by using the appropriate interest

factors.Accordingly,some interest rate must be used in the factors.This

interest rate is decided in advance and represents the rate-of-return criterion

that the company is using to evaulate its investment opportunities.If the

aggregate present worth of the project is positive,the return from the project

exceeds the rate-of-return criterion.If the present worth of the project is

negative,the project does not meet the rate-of-return criterion.

(Groover M.,Automotion,Production Systems and CIM

Practice Hall 1st edition,p. 49)

New definition:

Many

economists prefer the present worth method because it reveals the sum in

today's rupee that is equivalent to a future cash flow stream. For example, Rs.

110 expected one year hence is worth only Rs. 100 today, if the rate of

interest is 10 per cent, compounded annually. This means that Rs. 100 is the

present value of Rs. 110 to be earned one year hence.

In the

present worth method, the present worth of all cash inflows (revenues) is

compared against the present worth of all cash outflows (costs) associated with

an investment project. In this method of comparison, the cash flow of each

alternative will be reduced to time zero by assuming an interest rate i. Then,

depending on the type of decision, the best alternative will be selected by comparing

the present worth amounts of the alternatives. The difference between the

present worth of the cash flows (inflows — outflows) is referred to as the Net

Present Worth (NPW) which determines whether or not the project is a feasible

investment.

Steps

Needed for Present Worth Comparison

The

following are the steps involved in present worth comparison:

1. Estimate the interest rate that

the firm wishes to earn on its investment.

2. Determine the service life of

the project.

3. Ascertain the cash inflows over

each service life

4. Find out the cash overflows

over each service period

5. Calculate the net cash flows

(inflows-outflows)

If

there is a single investment proposal, then the decision whether a project will

be selected or rejected can be made accordingly.

·

If

PW > 0, then the proposal will be selected. A positive NPW means that the

equivalent worth of the inflows is greater than the equivalent worth of the

outflows. So, the project will make profit.

·

If

PW < 0, then the investment project should he rejected. A negative NPW means

the equivalent worth of the inflows is less than the equivalent worth of the

outflows.

·

If

PW= 0, then one should remain indifferent to the investment.

In case

there are mutually exclusive alternatives, then the present worth cash flows

can be calculated by two prominent methods:

·

Revenue-based

present worth

·

Cost-based

present worth

In a

revenue/profit-based cash flow diagram, the profit, revenue, salvage value (all

inflows to an organization) will be assigned with a positive sign. The costs

(outflows) will be assigned with a negative sign. In a cost-based cash flow

diagram, on the other hand, the costs (outflows) will be assigned a positive

sign and the profit, revenue, salvage value (all inflows), etc. will be

assigned a negative sign. In revenue-based cases, the decision is to select the

alternative with the maximum profit. Thus, the alternative with the maximum

present worth will be selected. In cost bases cases, if the decision is to

select the alternative with the minimum cost, then the alternative with the

least present worth amount will he selected.

(Sasmita Mishra, Engineering Economics and

Costing, pg.96)

v

My definition includes more

information so makes it easy to understand the meaning of the method.

FACING CYCLE (IN

G-CODING)

Group: automation

|numerical control and programming

There

is no old definition

New definition:

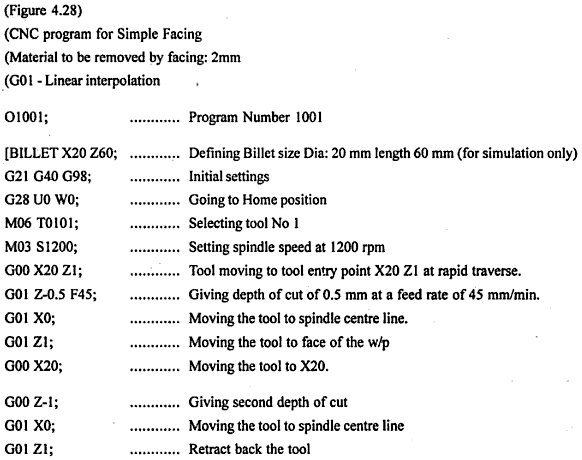

The

facing cycle is used when the major direction of cut is along the x axis. The

cycle causes the profile to be roughed out by facing control passes on to after

the last block of the profile. Two G72 blocks are needed to specify all the

values.

Sample:

Write a

manual part program for simple facing operation for the given component.

(C. Elanchezhan,G. Shanmuga Sundar, Computer Aided

Manufacturing, 420,427)

v My definition is sufficient

Great tips, many thanks for sharing. I have printed and will stick on the wall! I like this blog. Deep Draw

ReplyDelete