PHOTOLITHOGRAPHY (OPTICAL LITHOGRAPHY)

group: material process

Old

definition:

Optical

Lithography(also called photolithography) uses light as the writing material.

The drawn(greased) and undrawn(moistened) areas on the limestone in lithography

become bright and dark regions on a reticle or phptmask, the template of

optical lithography. Just as greased ink discriminately deposits on the

limestone, light passes only through the clear opening the mask. The

transmitted energy is recorded on a light-sensitive medium called the

photoresist.

(Alfred Kwok- Kit

Wong, Resolution Enhancement Techniques In Optical Lithograpy,p.2)

New definition:

An often-used

technique for device fabrication is photolithographic masking. Here, a film of

photoresist is applied to the substrate, and the photoresist is exposed to

light through a photolithographic mask. After exposure, the photoresist is

developed, which transfers the desired pattern to the photoresist (Fig. 6.3).

When the substrate is subjected to a chemical treatment, the photoresist

protects the surface, and thus the pattern on the mask is transferred to the

substrate. The photoresist is removed by stripping, which is essentially

dissolution of the photoresist in a nonuniform but fast way. Acetone is usually

used to strip resist, but in some cases a special stripper must be used. The

photoresist manufacturer generally makes such a stripper available.

Photoresists can be any of various photosensitive polymers. These polymers can

be applied by different techniques such as spinning or spraying. In spinning,

the thickness of the film can be expressed by this empirical expression:

Where t coating is the

thickness of the coating, K is a

proportionality constant, r is the

kinematic viscosity (mm2 s-1), and w is the number of revolutions per minute. The polymers are

sensitive to light of particular wavelengths, and when exposed to these the

chemical structure of the photoresist changes. Usually they are sensitive to UV

light, with the i-line of mercury (365 nm) being particularly popular. After

exposure to light, the photoresist is developed by using a particular chemical

solution. Some photoresists become more soluble in a developer after exposure,

some become less soluble. The photoresists that become more soluble are called

positive tone photoresists (Fig. (6.3); an example is AZ4562 photoresist. The

other type of photoresist becomes less soluble after light exposure, due to

cross linking of the polymer, and is called negative tone photoresist; an

example is SU-8.

(Oliver

Geschke,Henning Klank,Pieter Telleman,

Microsystem Engineering of Lab-On-A-Chip Devices, pg. 122)

My definition makes it easy to understand about this method by

given formulations and layout of process.

BLACK ‘ORLON’

group:

material

Old

definition:

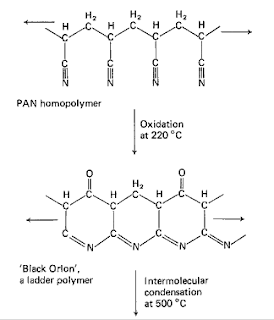

Black Orlon is a

ladder polymer obtained by regulated pyrolysis of polyacrylonitrile. The

structure of black orlon contains H,C and N atoms. Fibres of black orlon are

highly tough and find applications in fibre reinforced plastics.

(A.K. Bhargava,

Engineering Materials: Polymers Ceramics And Composites, 200, page 118)

New definition:

For some time it

has been known that PAN fibres blacken on heating in air at 220 0C

and that this 'black Orion' is remarkably flame-proof and stable. Such

stabilization by oxidation permits the formation of oriented ladder polymer

whilst reducing the intensity of the exothermic peak, which would otherwise

build up if the oxidation process were to be omitted. After stabilization, the

modified ladder molecules have a high enough glass transition temperature to

retain any preferred orientation imposed in the original polymer, even subsequent

to a carbonization process.

The proposed

mechanism of carbonization is illustrated also in fig. 9. The ladder molecules

coalesce progressively to form the ribbons characteristic of all polymeric

carbons. It should be stressed that the structures drawn in fig. 9 are

essentially related to isotactic homopolymers, whereas the fibres used to make

high stiffness, high tenacity carbon fibres are atactic copolymers. This makes

the true mechanism difficult to interpret.

(G. M. Jenkins,K.

Kawamura, Polymeric Carbons,

pg.31-33)

Old definition is also good because of being simple and easy to

understand but against my definition is more satisfactory to observe the

structure.

VGCF (VAPOR

GROWN CARBON FIBERS)

group:

material

Old

definition:

VGCFs comprise a

large family of filamentous nanocarbons.Thwy can be distinguished in terms of

arrangement of the graphane layers in their molecular scale structure.They can

be plate-like with near paralell graphane layers that are approximately

perpendicular to the fiber axis or they can have the 'fish-bone' microstructure

with stacked cones of graphane planes.(Functional Fillers For Plastics,Marino

Xanhtos,p:194)

New definition:

Carbon fibers

produced by direct growth from the vapor phase, i.e., vapor grown carbon fibers

(VGCF)is an another variety of reinforcement with high mechanical and thermal

properties and significant commercial potential. These are also called catalytic

chemical vapor deposition (CCVD) carbon fibers. These fibers arc produced by

catalytic decomposition of a hydrocarbon such as benzene, methane, or propane

at 1000-I 500o C in the presence of a transition metal (Fe, Ni, or

Co) or metallo-organics such as ferrocene. (C 5H5)2,Fe

(Tibbetts ei at 1987). The catalyst plays a vital role in the growth of VGCFs.

The carbon fiber yield is enhanced if a catalyst with a small but broader

distribution of particle sizes is used. VGCFs are produced in short lengths (50-70

mm) and small diameter (0.5-2 pm). Benzene, or other hydrocarbons which

generate benzene during decomposition, are preferred as a precursor for a

higher rate of production. These fibers have also been produced from low cost

sources such as linz-donawitz converter gas and coal-derived hydrocarbons.

These fibers possess very high mechanical properties but have a large scatter

in the values.

The structure, and

thus the mechanical properties of VGCF, are independent of the precursor gas

source employed, but are extremely dependent on processing parameters such as

temperature of growth, type and distribution of catalyst, etc. The aspect ratio

of VGCF is found to be dependent on catalyst to hydrocarbon flow ratio. Low

temperature deposition (<9000C) results in vermicular filaments,

while high temperatures (1500-25000C) favor the growth of long,

straight filaments. Since VGCF are produced in a one-step process, these

possess significant commercial potential as low cost carbon fibers.

Based on electron microscopic

studies on the structure of the fibers, the growth process has been proposed

consisting of two parts (Endo et al. 1977). In the primary process a thin tube

of carbon is formed by catalytic growth on a catalyst particle. This is followed

by secondary growth onto the first tube. VGCF consist of turbostratic carbon

layers parallel to the fiber axis arranged in annular concentric sheets like

rings in a tree trunk. The core is more perfectly ordered while the secondary

sheets may contain some defects. VGCF are graphitizable carbons, and when heat

treated to more than 2500 0C, develop a well-orianted graphite

structure and increase in density and Young’s modulus.

(Andreas Mortensen, Concise Encyclopedia of Composite

Materials, pg. 93 )

My definition is so good against the older definition because

the previous one is so poor to explain the process.

CHEMICAL

SYNTHESIS

group:

material chemistry

Old

definition:

Chemical synthesis

is uniquelly positioned at the heart of chemistry, the central science, and its

impact on our lives and society is all pervasive. For instance, many of todays

medicines are synthetic and many of tomorrows will be conceived and produced by

synthetic chemist. To the field of synthetic chemistry belongs an array of

responsibilities which are crucial for the future of mankind, not only with

regard to the health, material and economic needs of our society, but also for

the attainment of understanding of matter, chemical change and life at the

highest level of which the human minds is capable.

(Chemistry 1981-1990,

B.G. Malmström, p.686)

New definition:

A century and a half later

Crnforth defined chemical synthesis as "international construction of molecules

by chemical means". The period from the second half of the 19th century

through the first half of the 20th century witnessed three primary pursuits in

the field of organic chemistry: (I) the elucidation of the structures of

natural products, (2) the investigation of basic reactions, and (3) the

preparation of new chemical substances (Fig. 1.1-1). These activities continue

to this day simplified by modern technology. Organic chemists pursue new activities

as %sell, and synthetic organic chemistry is now associated with biology,

medicinal chemistry, and materials sciences.

Any chemical

synthesis can be resolved into three basic processes as shown in Table I. The

information associated with each process must be captured and stored in an

automated procedure. The design process is a melding of target selection with

synthetic methodology. For a traditional synthesis, the potential targets are

only limited by the chemist's skill. Because the glassware used for traditional

syntheses is of modular design and can be built into a large number of

configurations, the reactor design generally does not impose any restrictions

on the reactions that can be run. Thus the chemist can select any method for

synthesis of the desired targets. The commercial availability of chemical

building blocks becomes a major factor in library design. Due to the long lead

times for custom-synthesized building blocks, the synthesis of compound

libraries for the drug discovery are often restricted to commercially available

starting materials. Availability of building blocks also impact the selection

of the chemistry used to synthesize the final products. The synthetic

methodologies are restricted to those chemical reactions that use the available

building blocks. The synthetic transformations must also be selected that

provide the best chance of success (e.g., high yield limited reaction steps,

solution or solid phase techniques, easy to handle reagents, common solvents,

etc.).

(Tomás Hudlicky,Josephine

W. Reed, The Way of Synthesis: Evolution

of Design and Methods for Natural Products, pg. 3-4)

(By Swartz, Analytical Techniques in Combinatorial

Chemistry, pg.177)

My definition is richer for an engineer to understand how and

why chemical synthesis used in our lifes.

CHEMICAL VAPOR DEPOSITION

group:

material process

Old

definition:

Chemical vapor

deposition (CVD) is a widely used materials- processing technology. The

majority of its applications involve applying solid thin-film coating to

surfaces, but it is also used to produce high-purity bulk materials and

powders, as well as fabrikating composite materials via infiltration

techniques. It has been used to deposit a very wide range of materials. The

majority of the elements in the periodic table have been deposited by CVD

techniques, some in the form of the pure elements, but more often combined to

form compounds.

(Jong-Hee Park,T.

S. Sudarshan, Chemical vapor deposition, p. 1)

New definition:

Thermal CVD (or

vapor plating) is the deposition of atoms or molecules by the high temperature

reduction or decomposition of a chemical vapor precursor species, which

contains the material to be deposited. Reduction is normally accomplished by

hydrogen at an elevated temperature. Decomposition is accomplished by thermal

activation. The deposited material may react with other gaseous species in the

system to give compounds (e.g. oxides, nitrides). Chemical vapor deposition

processing is generally accompanied by volatile reaction byproducts and unused

precursor species. Chemical vapor deposition has numerous other names and

adjectives associated with it such as vapor phase epitaxy (VPE) when CVD is

used to deposit single crystal films, metalorganic CVD (MOCVD) when the

precursor gas is a metalorganic species, plasma-enhanced CVD (PECVD) when a

plasma is used to induce or enhance decomposition and reaction, and low

pressure CVD (LPCVD) when the pressure is less than ambient. Plasmas may be

used in CVD reactors to "activate" and partially decompose the

precursor species. This allows deposition at a temperature lower than thermal

CVD and the process is called plasma-enhanced CVD (PECVD) or plasma-assisted

CVD (PACVD). The plasmas are typically generated by radio frequency (rf)

techniques. Figure 1.2 shows a parallel plate CVD reactor that uses rf power to

generate the plasma. This type of PECVD reactor is in common use in the

semiconductor industry to deposit silicon nitride (Si3N4) and phosphosilicate

glass (PSG), encapsulating layers a few microns thick with deposition rates of

5-100 nm/min. at low pressures, concurrent energetic particle bombardment

during deposition can affect the properties of filns deposited by PECVD.

CVD Diamond Cutting

Tools

Chemical vapor

deposition processes now permit the economical manufacture of large sizes and

commercial quantities of synthetic diamond at temperatures less than 1000 0C(1830 °F) at relatively low

pressures (<100 kPa, or 1 atm). CVD diamond has as low a coefficient of

friction as Teflon, is as hard as natural diamond, and exhibits thermal

conductivity four to five times that of copper. Tools coated with diamond can

machine a wide variety of nonferrous materials. The coating exhibits high

lubricity, generates low cutting forces. wears slowly, and does not heat-distort

the workpiece. The properties of single-crystal diamond, CVD diamond, and PCD

arc compared in Table 9.

The CVD process can

he defined as the deposition of a solid on a heated surface via a chemical

reaction from the vapor or gas phase. It belongs to the class of vapor-transport

processes that arc atomistic in nature, that is, the deposition species are

atoms or molecules, or a combination thereof.

The CVD of diamond

requires the presence of atomic hydrogen, which selectively removes graphite

and activates and stabilities the diamond structure. To dissociate hydrogen

requites a high-energy source. In addition to the need for atomic hydrogen,

other factors, such as energy output and the presence of oxygen, have been

shown to be important as well. Although the deposition mechanism associated

with CVD processing of diamond is complex, the basic reaction involves the decomposition

of a hydrocarbon, such as methane:

CH4→C(diamond)+2H2(g)

The reaction can be

activated by microwave plasma or direct current (dc) plasma arc.

Applications

CVD and PCD diamond

can be used in many of the same applications, but PCD is more suited to

roughing and to machining applications and materials that require high fracture

toughness of the tool. CVD diamond excels at finishing, semi-finishing, and continuous

turning applications because of its superior wear resistance, and its hardness

allows it to produce more precisely machined parts. Materials commonly machined

by CVD diamond include high-silicon content aluminum casting alloys, aluminum

matrix composites, graphite, fiber reinforced plastics and other nonhomogeneous

materials, carbon-carbon composites, polyvinyl fluoride, fiberglass, Kevlar,

honeycomb materials(such as Nomex), Inconel, and copper alloys.

(ASM International.

Handbook Committee, Tool Materials,

pg. 98)

(Donald M. Mattox, Handbook of Physical Vapor Deposition (PVD)

Processing, pg.6)

My definition

is so long but it gives more detailed example for why it is used and why it is

important for machining processes.

hangi açıklamanın daha iyi olduğunu belirtebilir misin?

ReplyDeletekelimeleri düzenleyip eksikleri tamamlamak için perşembe gününe kadar vaktimiz var lisans öğrencileri olarak bugüne kadar bekleyip daha sonra değerlendirme yapmanız gerekiyor.

ReplyDelete