[Old]

This type of conveyor is used to transport various shapes of products such as boxes or materials which extend over several rollers. This type consists of cylindrical rollers supported in frames over which materials are allowed to move. They are driven by power or gravity. These are of different varieties and can move material in horizontal direction as well as from the upper floor to lower floor.

These have a long life readily assembled and installed, easy to adjust and used for handling large variety of loads. Load with rigid and smooth base are moved on the roller conveyors. Other items can be moved after placing themon flat boards. Pitch of the the rollers should be such that minimum of 3 rollers must remain under load at all times, spacing is generally kept at 8 cm, 10cm or 15cm.

There are two main type of roller conveyors, with different sub-types:

- Gravity type or Unpowered type

- Stationary

- Mobile

- Powered type

- Chain driven

- Gear driven

- Belt driven

(Arora K.C., Shinde V.V., Aspects of Material Handling, pg.94, Kayra Ermutlu)

[New][Better]

Roller conveyors can be operated with or without power for movement. Usually they are powered with a chain drive for easy movement of material. The rollers are fitted with end sprockets which are in turn driven by an endless chain. The roller conveyors are invariably used for transportation of packages, cartons, pellets or any other packaged material. They are not normally used for unpacked food materials. They consist of a series of rollers fixed on either sides with ball bearings. The rollers are closely placed with a small clearance in between so that each roller rotates independently. While rotating, they transport the carton placed on them. A typical roller conveyor is shown in Figure 26.12 which moves horizontally only. Some roller conveyors are made to turn the movement of the material horizontally as shown in Figure 26.13. Normally. whenever

we need to change the direction of movement of the packaged material/cartons, either roller conveyors or slat belt conveyors alone are preferred. Roller conveyors have an additional advantage that the moving material is never blocked as long as its size is bigger than the clearance between each roller. Roller conveyors can also be made for movement af the material in the inclined position also both in upward and downward direction (as shown in Figure 26.14). The inclination should be 10°-12° for gravity flow or power driven rollers. Higher degrees of inclination may result in slipping or scaring of the packages. Chain driven rollers can be used for heavy duty operation where the speed of conveying could be as high as 2.5 m/s, whereas belt driven rollers are used only upto 0.25 m/s. They can be fitted with reversible drives so that the material can be moved in either direction. In some conveyors, provision is made for intermediate discharging of material also.

(Fundamentals Of Food Engineering, Rao, pp. 504-505)

[Old]

Continuous chips coming out during machining in machine shop. These types of chips are obtained while machining ductile material such as mild steel and copper. A continuous chip comes from the cutting edge of a cutting tool as a single one piece, and it will remain as one piece unless purposely broken for safety or for convenience in handling. Formation of very lengthy chip is hazardous to the machining process and the machine operators. It may wrap up on the cutting tool, work piece and interrupt in the cutting operation. Thus, it becomes necessary to deform or break long continuous chips into small pieces. It is done by using chip breakers. Chip breaker can be an integral part of the tool design or a separate device.

(Introduction to Basic Manufacturing Processes and Workshop Technology,Rajender Singh,p 402)

[New][[Better]

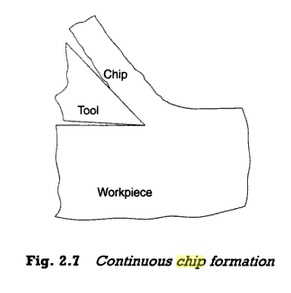

Continuous chips are normally produced when machining steel or ductile metals at high cutting speeds. The continuous chip which is like a ribbon flows (Fig. 2.7) along the rake face. Production of continuous chips is possible because of the ductility of metal (steel at high temperature generated due to cutting) flows along the shear plane instead of rupture. Thus on a continuous chip you do not see any notches. It can be assumed that each layer of metal flows along the slip plane till it is stopped by work hardening. Each of these layers get welded to the previous ones because of the high temperature, thus forming a continuous chip. Some ideal conditions that promote continuous chips in metal cutting are sharp cutting edge, small chip thickness (fine feed), large rake angle, high cutting speed, ductile work materials and less friction between the chip tool interface through efficient lubrication.

Continuous chips are the most useful chips since the surface finish obtained is good and the cutting is smooth. It also helps in having higher tool life and lower power consumption. However, because of the large coils of chips. chip disposal is a problem. For this purpose various forms of chip breakers have been developed which are in the form of a step or groove in the tool rake face. The chip breakers allow the chips to be broken into small pieces so that they can be easily disposed Off.

(Manufacturing technology: metal cutting and machine tools,

Posinasetti Nageswara Rao,2006,p. 9)

Posinasetti Nageswara Rao,2006,p. 9)

4)Butt Weld [Group:Manufacturing Method]

[Old]

The butt weld is a connecting weld between plates which is largely free from force flow diversion and hence has a low stress concentration factor.ıt makes a joint in the same plane or only at a slight angle.It has the following variants;square butt weld, single V butt weld, single U butt weld with or without root face, U and V welds also arise as double welds(Double V weld identical to X weld), and the raised edge butt weld.

(Dieter Radaj,Design and analysis of Fatigue Resistans Welded Structures, page 38)

[New][Better]

Butt welds in carbon—manganese steels, made by arc welding with consumables giving weld metal matching the parent metal strength, are as strong as or stronger than the steel itself. In very high strength steels it may not be possible or feasible to produce a weld metal of matching strength and so a weld metal of lower strength than the parent metal may have to be accepted. For most purposes then, a butt weld in common structural steels does not have to be taken into account when calculating the static strength of a structure in the sense that its strength may be considered to be identical to the parent metal. However if ductility, as much as strength, is a necessary property, such as in the plastic design of a beam to column joint, it is necessary to ensure that the whole joint, comprising the parent metal, its heat affected zone and the weld metal, can offer the required rotation of a section up to the specified limit state. This requires attention to the ductility of the weld metal and the ductility of the column flange material in all axes as well as to the design of the weld preparations and welding procedures so as to avoid defects such as lack of penetration and lack of fusion. These matters have a special significance in the case of earthquake resistant designs which demand extremes of ductility at the beam to column joints. The difficulties inherent in achieving such properties have been recognised and proposals have been made for the use of a beam design detail which induces the plastic hinge to occur at a position in the beam away from the welded beam to column joint.

To allow high ductility to be exploited particular attention must be paid to the notch toughness of both the parent and weld metals. This may be particularly important in the case of undermatching weld metals where plastic strain may occur in the weld metal whilst the parent metal remains in an elastic state.

For welded joints in aluminium alloys, whose strength may be reduced by the heat of welding, the application standards give strengths or factors which have to be used to account for this.

No comments:

Post a Comment